TUFFLON-P90 | CASE STUDY

SEAFOOD PROCESSING PLANT | SECONDARY CONTAINMENT

Date of Project

November, 2009

Substrate Material

Concrete with existing failed Epoxy coating

Type of Asset

Seafood Processing Factory

Location of Asset

Clontarf, Australia

Project Overview

The owner of a seafood processing factory needed the failed epoxy floor coating to be replaced in order to satisfy AQIS (Australian Quarantine and Inspection Service) requirements.

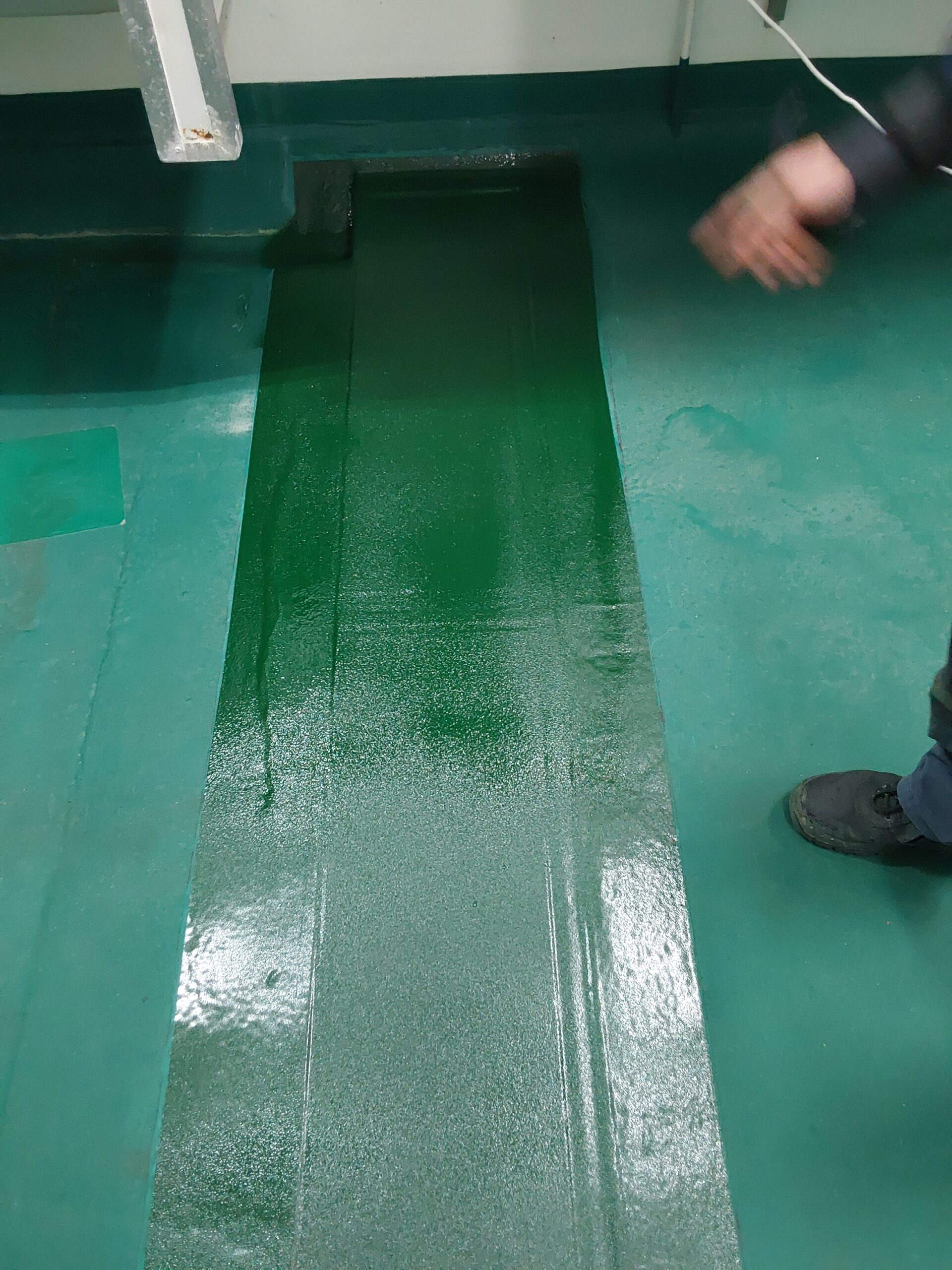

The Existing Failed Floor Coating

The existing coating was an Epoxy that had started to crack and peel away from the concrete substrate in many areas. In other areas, the existing Epoxy was still in usable condition. While Epoxies display good chemical resistance and outstanding adhesion, they are not elastomeric and will not move or stretch to accommodate movement in the substrate. Consequently, it is common to see them cracking and flaking off the substrate after some time in service.

The New Floor Coating Requirements

The new floor had to have the following features:

- Seamless - not allow liquids to penetrate the subgrade area below

- Strong adhesion to the concrete

- Able to withstand movement in the concrete without cracking and peeling

- Non-slip, yet remaining easy to clean using a mop and Sodium Hypochlorite

- Durable and resistant to the chemicals and other liquids typically found in such an environment

- Non-Toxic

- Would resist heavy items being dropped onto it

- Can be repaired

The Proposal

Liquimix offered the following system based on the top coat being Tufflon-P90 Pure Polyurea:

- Remove as much of the failed Epoxy as possible using either a grinder or water blaster

- Clean and dry the concrete

- Apply a suitable concrete sealer

- Apply Tufflon-P90 Pure Polyurea in green colour to 3mm DFT

- Ensure a final mist coat is applied immediately to foot trafficable areas to increase surface friction

The above system is fast to install, environmentally friendly, and does not contain any VOC's, making it safe to use in Food Processing Factories

The Tufflon-P90 floor lining system provided an expected service life of 20 years, and the solution worked efficiently and effectively and is still performing at a high-quality level, 14 years after application. Tufflon-P90 is the perfect remedial solution for substrates that have been previously coated and are experiencing peeling or cracks. The general recommendation for future projects is to use Tufflon-P90's tough qualities and smooth surface finish to provide outstanding, lasting results for factory floors.

Products

- Aralox-21

- Tufflon-P90

- Fine Sand

Surface Prep

- Remove Flaking and damaged Epoxy coating using a 3,000 psi water blaster at 21 L / minute fitted with a Turbo Nozzle

- Prepare all in-floor drains before application of Aralox Epoxy concrete sealer

- Mask using wire-trim tape

- Prime with Aralox-21 Epoxy primer with fine sand embedded to increase adhesion

- Apply Tuffon-P90 Pure Polyurea at 3mm DFT in green colour

- Apply a final mist coat of Tufflon-P90 to increase in surface friction